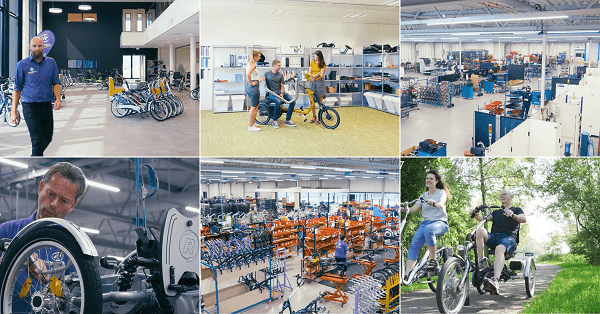

Manufacturer of special needs bikes Van Raam in the news

Since Van Raam's relocation in January 2019, there has been a lot of media attention for the manufacturer of special needs bicycles. In November 2019, De Gelderlander (a Dutch newspaper) published a large article about Van Raam. In this article the Gelderlander talks about the sustainable building and bicycle test track, the history, Van Raam as world market leader and the prizes it has won. Read more about the article by the Gelderlander here.