5 questions for the Van Raam management - Video

The management of Van Raam consists of 3 persons; Marjolein Boezel, Jan-Willem Boezel and Ronald Ruesink. Get to know the directors better by watching this video in which they are asked 5 questions.

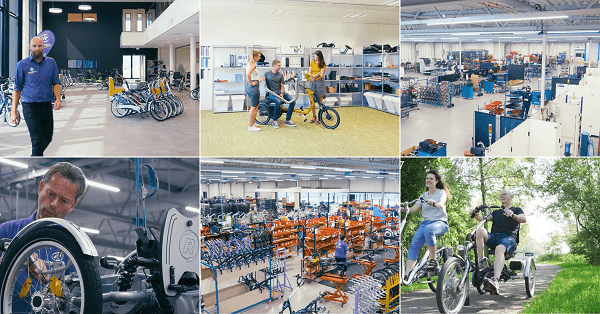

Van Raam produces uniquely special needs bicycles and specializes in tricycles, transport bikes, scooterbikes, wheelchair bikes, tandem bikes, double rider bikes, and low step trough bikes (also known as comfortbikes). Each model is also available as an electric bike (Pedelec).

vanRaam is a Dutch producer of unique custom bikes. Want to know more about our company or special needs bikes?

Menu

Search

Our bikes

News

Van Raam made a video of the Van Raam Research and Development department in order to get an overview of the workflow. You will see different steps of how a new bike is developed at Van Raam. Read more about this in the following article, also see what the following steps are that are necessary for a bike manufacturer like Van Raam to get a complete high-quality special needs bicycle.

The journey of a (new) custom-made bike starts by Van Raam at the Research and development (R&D) department. If there are new ideas for a bike they mostly comeamong other things from the following sources: the market and from the needs of the target group.

In order for the new product idea to be a sales success, it is important that the idea is not only technically but also commercially well-founded. Also, our product engineering of this department is involved with the continuous optimization of the current range of products.

View the video of the R&D department to get a visual look into our research and development department at Van Raam.

Van Raam Research and Development

If the idea of a new bike is set,Van Raam goes through a development process. It begins among other things with the research of the target market to determine the focus of the new special needs bike.

Furthermore, this result leads into a phase where ideas are being generated.

With in the creation of a new bicycle, design may not be forgotten. A lot of the parts of the bicycles are drawn in a 3D program, called Solid Works. Furthermore, there are technical drawings made for the production and dimensional drawings for the assembly.

Tests of the different options, colors and setting and assemblies can be best fulfilled with a prototype for example on our bike test track, that is also co-developed with the R&D department.

A prototype is an early model of a product, handmade or via rapid prototyping, which tests the occurring forces, the operation or fit of parts and prepares the production. In this Department electrical and mechanical engineers sit next to Embedded Software Engineers and IT Developer together in the R&D department at Van Raam in order to get the best communication and the best product with the highest quality.

Is the bicycle is developed the production of the bike can begin. Read here further to get and overview on the followings steps the bike must go through in order to be delivered to the customer.

Step 1: Van Raam Research and Development Department

Step 2: Bicycle Frame Production

Step 3: Van Raam Bicycle Frame Blasting and Powder-coating

Step 4: Collecting Parts

Step 5: Producing wheels in the wheel assembly

Step 6: Van Raam Bike Assembly

Step 7: Testing and final inspection

Step 8: The bike is on the way to you!

To get more and deeper information the production steps read the article “How Van Raam bikes are produced”

In addition to the videos of the Research & Development Department, Van Raam has more videos to watch. On our video page you will find videos about our bicycles, our (new) bicycle factory, our employees, about famous dutch people on our bicycles and about Van Raam in the media.

The management of Van Raam consists of 3 persons; Marjolein Boezel, Jan-Willem Boezel and Ronald Ruesink. Get to know the directors better by watching this video in which they are asked 5 questions.

Have you seen the Van Raam product guide? This complete product guide contains a lot of information about the tricycles, the mobility scooter bike, low step through bikes, the walking aid, duo bikes, tandems, wheelchair bikes, the transport bike and everything else you need to know about Van Raam and a Van Raam special needs bike.

Van Raam is manufacturer of special needs bicycles. But what does Van Raam actually look like and how are the special needs bicycles being made? Take a look inside Van Raam with the sneak preview!

As a manufacturer of special needs bikes, we aim to offer sustainable and contemporary mobility to as many people as possible. We do this for people with disabilities, but also for people who no longer dare to ride a traditional two-wheeler because they are afraid of falling or suffer from balance problems.

We are happy to assist you! Please check our contact page or contact us directly using the options below.