Measures related to the Coronavirus (COVID-19) at Van Raam

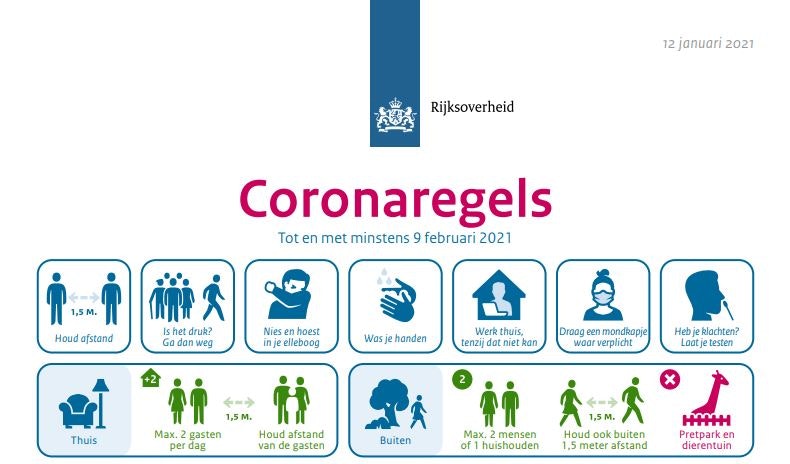

Van Raam is open for a test ride by appointment. Van Raam follows the guidelines of the Dutch National Institute for Public Health and the Environment (RIVM) with regard to the coronavirus.

Van Raam produces uniquely special needs bicycles and specializes in tricycles, transport bikes, scooterbikes, wheelchair bikes, tandem bikes, double rider bikes, and low step trough bikes (also known as comfortbikes). Each model is also available as an electric bike (Pedelec).

vanRaam is a Dutch producer of unique custom bikes. Want to know more about our company or special needs bikes?

Menu

Search

Our bikes

News

A lot of action is being taken to fight corona. A lot is also being done to counter the shortage of medical materials. At the moment there is a great shortage of mouth caps and splash caps in the health care sector. Van Raam, together with youth from the Achterhoek (a region in the Netherlands), started the fight against the coronavirus by making 3D printed parts for splash caps. Read more about this in the article.

Van Raam has two different types of 3D printers and a total of four 3D printers. All these printers are now used to make a 3D printed part that is needed for splash caps. In this way Van Raam supports the young people of the Achterhoek(a region the Netherlands) with scaling up the production numbers of these parts for the splashcaps. The splash caps are used as protection in healthcare.

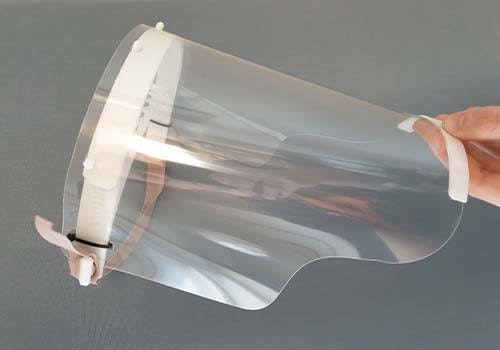

The part that is printed with a 3D printer is a bracket to which a transparent protective cap is mounted. The bracket is made up of two parts.

Van Raam prints three parts at the same time on each 3D printer. After 7.5 hours printing time these three parts are ready. One part has a print time of 2.5 hours.

As soon as the parts are printed, they are collected and brought to Hogeschool Zeeland in Vlissingen. Here, the parts are disinfected and the protective cap is mounted to the bracket. As soon as this is done, the splash caps are given to the White Cross. They ensure that the splash caps are then distributed to the parties applying for these protective caps. The ambulance service of the White Cross in Doetinchem, for example, uses the splash caps and they are used for the White Cross North and East Gelderland, they get 200 splash caps.

On the pictures below you can see that some of the splas caps are delivered at the ambulance service from the White Cross in Doetinchem.

One of the 3D printers that Van Raam uses is the FDM 3D printer of the brand DDDROP. Three of these printers are used to make the 3D printed parts for the splash caps. In the video below you can see how the printer is printing the parts. In the article 'Bicycle parts from the 3D printer at Van Raam' you can read how this printer works and you can find a video of the other 3D printer at Van Raam.

Van Raam 3D printer produces parts against corona

In the past period there have been dozens of young people in the Achterhoek who have built their own 3D printer together with their father or mother. This was an initiative of 'Samenwerkende Industriële kringen Achterhoek' and 8RHK ambassadors (Achterhoek ambassadors). Industrial designer Alexander Bol from Zeeland placed a message in the newspaper on March 31st in which he called on people who have a 3D printer at home to start printing the parts. After this call the young people in the Achterhoek who have their own 3D printer came into action. At this moment printers in Winterswijk, Aalten, Berkelland, Ulft and Varsseveld are being used to print the 3D parts. Watch more about this in the video below (video in Dutch).

At Van Raam all 3D printers are frequently used for printing bicycle parts and for printing tools for the production and assembly departments. Both types of 3D printers work with a different technique. In the pictures below you can see how the same part is printed in two different ways. Would you like to read more about the bicycle parts Van Raam makes with the 3D printers? Read more about it in the article 'Bicycle parts from the 3D printer'

Also the large 3D printer at Van Raam, the HP Multi Jet 3D printer is used for printing the parts.

Here you can see the parts as they are printed with the HP printer.

Here you can see the three FDM 3D printers of the brand DDDROP.

The printed parts with the 3D printer. Here you can see the design of the brackets. In total there are 3 parts here so that 3 splash caps can be made.

Van Raam believes that innovation is very important. This means continuously looking at how our bicycles, production process and assembly can be improved or even renewed. Watch our company movie or go to the innovation page on our website and find out everything about the latest techniques at Van Raam.

More action is being taken to fight corona. By developing a protection screen for the Fun2Go duo bike, people canride the Fun2Go together again, without (possibly) infecting the other person. Want to know more about the screen? Click the button below.

Van Raam is a manufacturer of special needs bicycles for people with a disability. Each bicycle is produced in Varsseveld. Would you like to know which products the 3D printer is normally used for? Take a look at all our bicycles here.

People, who cannot ride on a regular bicycle, look for a proper and safe alternative.

The vanRaam wheelchair bikes are used to enable a wheelchair dependent person to travel by cycle.

The two persons have a good view and can communicate well with each other due to the seats being next to each other.

The low step through bikes from vanRaam enable people to get on their bikes easier.

The compact electric scooter bike is designed for people with stability problems or variable energy level.

Our transport bikes are for children or adults who cannot or do not want to take part in traffic on their own or for recreational use.

Van Raam is open for a test ride by appointment. Van Raam follows the guidelines of the Dutch National Institute for Public Health and the Environment (RIVM) with regard to the coronavirus.

Van Raam thinks innovation is very important. There is a continuous search for ways to improve or even renew the special needs bicycles and the production processes. One of the innovative techniques used is printing bicycle parts with a 3D printer. Read more about the 3D printing of bicycle parts at Van Raam in this article.

Van Raam is a manufacturer of adapted bikes. To produce the bikes, a lot of innovative techniques are used, including the 3D printer. The 3D Print Magazine had written about why Van Raam uses this technique. Read in this article more about the article in the 3D print magazine and innovation at Van Raam.

Tweewieler visited Van Raam and wrote an article about how Van Raam uses 3D printing in the production of special needs bicycles. Read the article and discover more about innovation at Van Raam.

We are happy to assist you! Please check our contact page or contact us directly using the options below.