Have a look at Van Raam in 360 degree videos

Have a look at Van Raam in 360 degree videos

Van Raam produces uniquely special needs bicycles and specializes in tricycles, transport bikes, scooterbikes, wheelchair bikes, tandem bikes, double rider bikes, and low step trough bikes (also known as comfortbikes). Each model is also available as an electric bike (Pedelec).

vanRaam is a Dutch producer of unique custom bikes. Want to know more about our company or special needs bikes?

Menu

Search

Our bikes

News

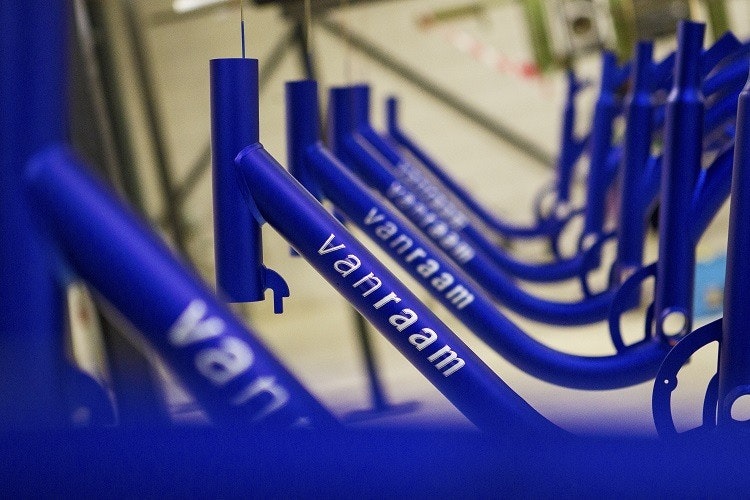

Would you like to know how and where the Van Raam special bikes get their environmentally friendly powder coating? Watch our 360 degree video in the paint shop. Control yourself in which direction you want to look.

Down below are two video’s of the Van Raam paint shop

If you want to watch the video in 360 degrees on your smartphone, you must open the video in the YouTube app. Otherwise, the video will play here on the website and on the YouTube mobile website in 2D and not in 360 degrees.

Tip: the spoken language in the video is Dutch, you can turn on English subtitles

360 degree video tour in Van Raam paint shop

How does a Van Raam bicycle get its color?

In the paint shop, which covers an area of 1,350 square meters, Van Raam's special bicycles are powder-coated in RAL colors by approximately ten man in two, paint booths. One of the painting lines works automatically and applies the primer to the frame in the other the paint and top coat are applied by hand.

Powder coating is an electrostatic coloring process. Powder coating is done after blasting (in production) where the frame is positively charged. The powder is negatively charged and therefore attracted to the positively charged frame.

It is attempted that first all frames of the same model are sprayed in the same color one after the other e.g. all (RAL 7026) granite gray Easy Rider.

Are all bicycles provided with the color and there are still other bicycles which need this color? Now all bicycles which should get that same color are sprayed. Most of the bikes get 3 coats of powder:

A primer

The desired RAL color

A top coat/clear coat. The clearcoat can be a gloss or matte paint.

After the undercoat the stickers are applied to the frame, after that the topcoat gets sprayed on.These coating do not only protect the colour, but also the stickers. This ensures longer visibilty and better protection for the stickers.

For the primer that means the undercoat, the frame goes through a scanner so the system knows which frame is coming. Here 6 nozzles are set. This is done automatically. There is still someone present who extra "sprays" places that cannot be reached by the machine. The paint layer and the top coat are sprayed on completely by hand.

After each coat of paint, the frame goes into the oven at 200°C. Here the powder melts in the heat. There are two different lanes in the oven.

The frame stays there for 30 minutes, up to 20 hooks can hang in the oven (2 sides 10 pieces per side).

The frames that come out of the oven go to the heat recovery zone and cool there. They also heat up the next series of frames coming into the oven to 80°C. The frames from the oven go to the heat recovery zone to cool down to 30°C before the next powder coating is applied or before they leave the paint shop for assembly.

The production system indicates on which hook the frame will be hung in the paint shop. The "painter" knows from the same system what color the frame will be. There are a total of 75 hooks from which frames and bicycle parts can be hung.

The powder, which is sprayed onto the frame at high pressure, temporarily sticks and is then melted in an oven. This unique powder coating process not only makes the powder partially reusable but also solvent-free and produces less hazardous waste than traditional paints. When powder coating, we try to waste as little powder coating as possible to be environmentally friendly.

Each Van Raam bicycle has its own standard RAL color. Find out what standard colors our bikes have in the article "Default colors for Van Raam bikes". Optionally you can have your bike powder coated in one of the possible RAL colors of your wish. In this way it is possible to personalize your bike according to your taste.

See also the Van Raam production in our 360 degree video and learn more about how we make the bike frames.

Have a look at Van Raam in 360 degree videos

Are you curious how the Van Raam production in Varsseveld looks like? Take a look at our production in our 360 degree video and control youself in which direction you want to look.

Are you curious about the Van Raam showroom? Take a look at the 360 degree video tour in the showroom. Control yourself in which direction you see. Read more about our Sales deprartment in de article.

Do you want to know how it looks like where the Van Raam adapted bikes are assembled? Take a look at the 360 degree video in the assembly. Control yourself in which direction you see.

We are happy to assist you! Please check our contact page or contact us directly using the options below.