Discover our range of products

Van Raam produces uniquely special needs bicycles and specializes in tricycles, transport bikes, scooterbikes, wheelchair bikes, tandem bikes, double rider bikes, and low step trough bikes (also known as comfortbikes). Each model is also available as an electric bike (Pedelec).

About vanRaam

vanRaam is a Dutch producer of unique custom bikes. Want to know more about our company or special needs bikes?

Menu

Search

Our bikes

How vanRaam bikes are produced

In our factory in Varsseveld, we build custom bikes for children and adults with a physical disability and for people who seek more safety and stability when cycling.

vanRaam Company Film

Wondering what the vanRaam factory looks like and how our custom bikes are put together? Take a look at the vanRaam company film below, which depicts the entire production process of a custom bike. Also see what steps a Van Ram bike goes through and follow the Easy Rider tricycle through the factory.

vanRaam corporate video

Follow an Easy Rider tricycle through the vanRaam factory

vanRaam Bike design

In addition to our in-house production and assembly facilities, we also have our very own design department: the Research & Development (R&D) department.

In designing our bikes, we use the 3D software package SolidWorks to design bikes in full 3D. Read more in the article about vanRaam's research and development department.

Bicycle frame production

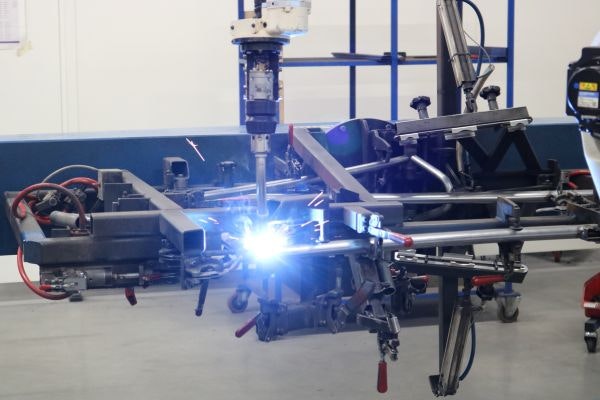

Many different steel pipes arrive in our production department, after which they are processed and eventually shaped into bicycle frames. Various machines are used to process the many pipes and a welding robot connects all parts together.

The company film shows the welding robot in operation, for example. The film also shows that in addition to all the machines, handcraft and technical knowledge is also required to produce a high-quality custom bike. Besides the welding robot, our factory also includes other machines, such as a 3D laser machine.

Would you like to know more about vanRaam's bicycle material? Then read the article: "What bicycle frame materials is a vanRaam bike made of?"

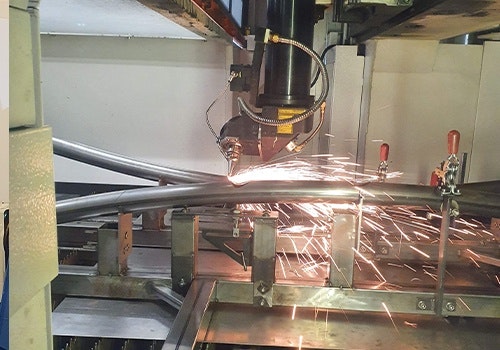

Mazak 3D laser machine

Our mazak laser machine performs all kinds of tube processing on the pipes that eventually form the bicycle frame. In the pictures and videos below, you can see that the laser machine is working on the frame of the Easy Rider and the Maxi tricycles.

Tube processing with 3D laser (Easy Rider tricycle)

Tube laser Maxi tricycle

Style BT 1000

One example of an innovative machine at vanRaam is the Style BT 1000 milling machine, which has several integrated tools that enable it to carry out various operations on pipes in rapid succession. For example, two Easy Rider tubes can be processed simultaneously.

Thanks to the simulation possibility, it is possible to see, before the machine is running, with which tools and in which order the machining operations must be made.

Take a look at the pictures below to see how the BT 1000 works.

vanRaam Bicycle Frame Blasting and Powder-coating

The blasting cabinet is used to blast the frame, after which it is powder-coated in our very own spraying workshop.

Each vanRaam bike can be powder-coated in (almost) any RAL colour. Read more about powder coating and choosing any color bike.

The price list on the product page of the relevant vanRaam bike shows the standard colour of every bike.

Collecting Parts

The warehouse collects all the components that the mechanics mount onto the bicycle frame.

These components differ per model. Moreover, because almost every bike can be equipped with different options and accessories, almost every bike is unique.

The most popular vanRaam add-ons can be found on the options page.

Producing wheels in the wheel assembly

We produce our very own wheels in our wheel workshop. The process starts with a rim, spokes, possibly a motor and ends with a complete wheel.

In the video below, we show how Rick manually holds a spoke in front of the correct spoke nipple on the rim and uses a machine to properly insert all the spokes. After inserting the spoke, the rim tape is prepared and the spokes are tensioned and balanced. The wheel is now ready, only the inner tube and outer tyre remain.

How does vanRaam make a wheel for adapted bicycles?

vanRaam Bike Assembly

In our assembly hall, all components are attached to the bike. Additional parts, such as an electric motor, foot fixation, backrest and stick holder are also attached here.

Testing and final inspection

Once the bike is ready, it is tested one last time by our team of final inspection engineers and the electronic system is activated.

Shipping

Once the bike has been approved, it is prepared for transport and is shipped to the dealer/bicycle shop.

Video's: How vanRaam make bicycles

Take a look behind the scenes of the recordings during the development of the Easy Rider Compact.

Making of: vanRaam Easy Rider Compact

Take a behind-the-scenes look at the recordings during the development of the vanRaam Fun2Go duobike

Making of: vanRaam Fun2Go duobike

About vanRaam

Want to know more about vanRaam? Please take a look at the pages listed under 'About vanRaam' and learn more about the company's history.

Assortment of vanRaam bikes

Want to know more about a specific vanRaam bike? Please take a look at the product page listing all vanRaam bikes and click on the desired bike.

Do you have any questions?

We are happy to assist you! Please check our contact page or contact us directly using the options below.