Tweewieler tells: 3D printing of 40.000 Van Raam parts

Tweewieler visited Van Raam and wrote an article about how Van Raam uses 3D printing in the production of special needs bicycles. Read the article and discover more about innovation at Van Raam.

Van Raam produces uniquely special needs bicycles and specializes in tricycles, transport bikes, scooterbikes, wheelchair bikes, tandem bikes, double rider bikes, and low step trough bikes (also known as comfortbikes). Each model is also available as an electric bike (Pedelec).

vanRaam is a Dutch producer of unique custom bikes. Want to know more about our company or special needs bikes?

Menu

Search

Our bikes

News

'It is one of the largest tricycles in the world ever printed,' says a proud Jan-Willem Boezel, technical director of Van Raam. The 3d printing of the Husky children's tricycle was the graduation assignment of Industrial Product Design student Sander Feuler. 'I think we're going to be 3d printing more and more in the future,' says Boezel.

The Husky tricycle has been discontinued from our range as of December 2024. Please take a look at our current tricycle range.

'We wanted to know whether it was possible to print a bicycle frame in 3d. It was really a research assignment with no commercial purpose,' says Jan-Willem Boezel, technical director at Van Raam. Fourth-yearIndustrial Product Design student at the HAN in Arnhem Sander Feuler was assigned to carry out the research assignment. Feuler looked at the functions of the current Husky and which parts are important to include in the frame. This showed that the chain guard and the luggage carrier had to be integrated into the frame, so that the whole thing becomes stronger and does not break.

A deliberate choice was made to 3d print a children's tricycle explains Feuler. With the 3d printing of plastic you have to take into account the strength of the material. The Husky tricycle is for children aged 2 to 4 years, with a maximum weight of 17 kilos. Plastic is suitable for that load. It's a different story when you want to print the Fun2Go side-by-side tandem in 3d. Then you have to look at other techniques.

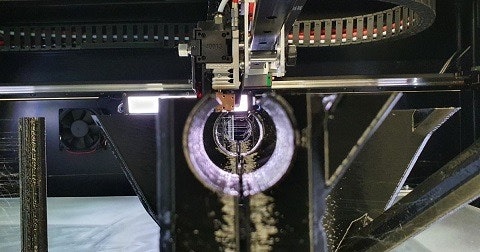

The frame of the children's tricycle was printed with a large FDM 3d printer. Regular 3d printers are usually 200 by 200 by 200 millimeters. The Dddrop Rapid One, on the other hand, has a size of 750 by 600 by 750 millimeters. This printer was supplied by CAD2M.

Feuler is very pleased with the 3d printed bicycle frame. 'There has never been a children's tricycle 3d printed before. The fact that we were able to achieve this result in such a short time is just fantastic!' Boezel fully agrees: 'Sander has really created something special and world-class. It is really unique that you can print the frame of a tricycle in one go.'The intention is that in the future the Husky will actually be printed in 3d. For this, research still needs to be done. For example, there are no regulations yet on which a 3d printed bicycle must comply.

Boezel thinks that Van Raam will apply 3d printing more and more in the future. 'Probably we will use different techniques per bike, because you have to deal with the strengths of the material. Perhaps we will use carbon for high-end bikes and plastic for children's bikes.' However, the technical director sees the biggest future for printing parts for bikes. In recent years, Van Raam has already printed several parts for their bikes. Read more about this in the article 'Bicycle parts from the 3d printer at Van Raam'.

Van Raam believes it is important to keep innovating. The 3d printing of bicycle frames is an example of this. Boezel: 'By using 3D printers, you can make a bicycle locally, custom-made and also by piece. This means you don't need stock, it's more sustainable and it gives you the opportunity to make customer-specific adjustments.' Are you curious about other innovative techniques within Van Raam, click on the button below.

Tweewieler visited Van Raam and wrote an article about how Van Raam uses 3D printing in the production of special needs bicycles. Read the article and discover more about innovation at Van Raam.

Van Raam thinks innovation is very important. There is a continuous search for ways to improve or even renew the special needs bicycles and the production processes. One of the innovative techniques used is printing bicycle parts with a 3D printer. Read more about the 3D printing of bicycle parts at Van Raam in this article.

Van Raam is a manufacturer of adapted bikes. To produce the bikes, a lot of innovative techniques are used, including the 3D printer. The 3D Print Magazine had written about why Van Raam uses this technique. Read in this article more about the article in the 3D print magazine and innovation at Van Raam.

Van Raam has been producing shortened and eccentric cranks with a metal printer since 2023. This has many advantages, including that this innovative way of producing is much more sustainable.

We are happy to assist you! Please check our contact page or contact us directly using the options below.