360 degree video tour of the Van Raam production

Are you curious how the Van Raam production in Varsseveld looks like? Take a look at our production in our 360 degree video and control youself in which direction you want to look.

Van Raam produces uniquely special needs bicycles and specializes in tricycles, transport bikes, scooterbikes, wheelchair bikes, tandem bikes, double rider bikes, and low step trough bikes (also known as comfortbikes). Each model is also available as an electric bike (Pedelec).

vanRaam is a Dutch producer of unique custom bikes. Want to know more about our company or special needs bikes?

Menu

Search

Our bikes

News

Van Raam is continuously looking at ways to improve production processes. One example is the Cobot (a collaborative robot) which is placed on the CNC lathe. Read more about the Cobot in this article.

*Some clips in the video are accelerated.

Cobot on the CNC lathe at Van Raam in production

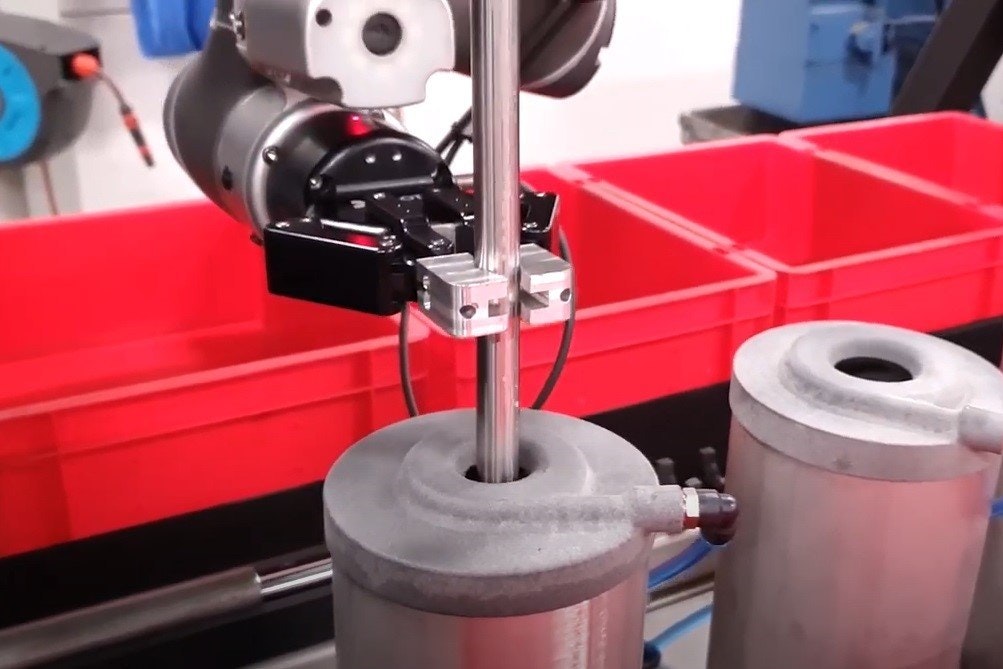

Van Raam manufactures the frames for the adapted bicycles itself. In the production department the tubes and parts for the frames are processed by different machines. The Doosan Lynx 220 lsy, a CNC lathe, is one of those machines. The CNC lathe has several integrated tools, which can be used to process tubes or bar material (seen in the beginning of the video).The lathe makes several parts for Van Raam bicycles, including the rear axles of all bicycles. In the video, you can see the Cobot removing a rear axle from the lathe. Wired Workers is the supplier of the Cobot at the lathe. They are proud to be a supplier to Van Raam.

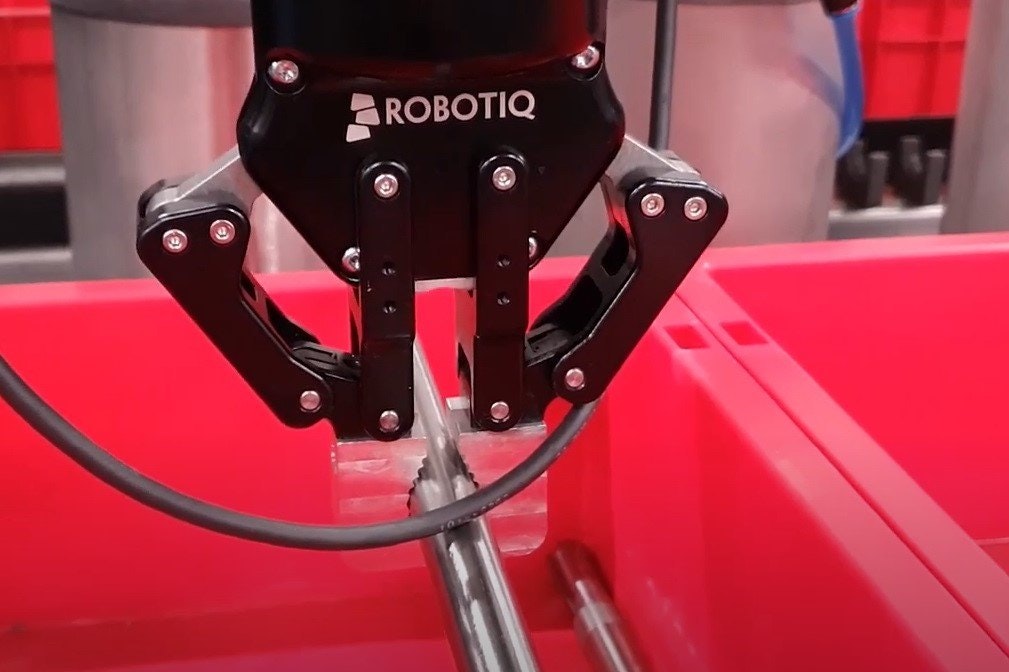

The CNC lathe has been extended with a Cobot. A Cobot, also called co-robot or collaborative robot, is designed to work together with humans in a common work area. "The speed of a Cobot is lower than industrial robots and because of this it is safer for humans to work together", explains Jarno Messing, engineer at Van Raam. An employee can safely stand next to the Cobot and perform his tasks, without the need for a fence. With an (industrial) robotic arm, safety fencing or environmental scanners are mandatory to ensure the safety of the workers.

The Cobot at Van Raam removes independently parts from the CNC lathe (seen in the video at 0.14) and cleans them (at 0.17), because sometimes oil or other residual material is left behind. It then places the parts in a crate (at 0.40). In between, the Cobot cleans itself (at 0.50) and removes residual material from the CNC lathe (at 1.02). Because the Cobot independently removes the products and residual material from the CNC lathe, the lathe can run without a worker. This increases the CNC lathe capacity because production can take place beyond working hours.

The arrival of the Cobot at Van Raam does not mean that jobs are lost. The CNC operator gets a more controlling than an executive task. The operator keeps an eye on the process and the quality of the products.

Are you curious about what the production department at Van Raam looks like? Watch our 360 degree video and take a virtual tour at for example the production department.

Innovation is an important pillar at Van Raam, we work continuously to improving our products and processes. Read more about the production methods, including 3D printing, that we use in our modern bicycle factory on the Innovation page.

Are you curious how the Van Raam production in Varsseveld looks like? Take a look at our production in our 360 degree video and control youself in which direction you want to look.

Van Raam is a manufacturer of adapted bikes. To produce the bikes, a lot of innovative techniques are used, including the 3D printer. The 3D Print Magazine had written about why Van Raam uses this technique. Read in this article more about the article in the 3D print magazine and innovation at Van Raam.

Van Raam is a manufacturer of adapted bicycles for people with a disability. The bicycles are manufactured in Varsseveld in one of the cleanest and smartest factories in the Netherlands. In our modern company, we have an innovative company policy and use innovative and modern techniques. To continuously improve these bicycles and remain innovative, Van Raam now also has a 3D scanner. Do you ask yourself what a 3D scanner is, why and what it is used for at Van Raam? Then read on and learn more!

Van Raam thinks innovation is very important. There is a continuous search for ways to improve or even renew the special needs bicycles and the production processes. One of the innovative techniques used is printing bicycle parts with a 3D printer. Read more about the 3D printing of bicycle parts at Van Raam in this article.

We are happy to assist you! Please check our contact page or contact us directly using the options below.