Discover our range of products

Van Raam produces uniquely special needs bicycles and specializes in tricycles, transport bikes, scooterbikes, wheelchair bikes, tandem bikes, double rider bikes, and low step trough bikes (also known as comfortbikes). Each model is also available as an electric bike (Pedelec).

About vanRaam

vanRaam is a Dutch producer of unique custom bikes. Want to know more about our company or special needs bikes?

Menu

Search

Our bikes

Innovation in everything we do

At vanRaam, innovation drives everything we do. From idea to unique bike, you work with the latest technologies to shape tomorrow’s mobility.

Working at vanRaam means building the mobility of tomorrow together with your colleagues every single day. You’ll work with the latest technologies, contribute to sustainable products, and be involved in the entire development process. From the very first idea to the delivery of a unique bicycle. You’ll have the space to experiment, innovate, and truly make a difference.

For us, innovation is not only about the product, but about the entire process. As an employee, you’ll collaborate with a multidisciplinary team to create smart solutions. We design and develop our bicycles fully in-house: from design and prototyping to production and assembly. As an engineer, developer, or production expert, you’ll have a direct impact on the final result.

We also invest in modern production techniques, automation, and digitalization, so you always work with the latest tools and methods. You won’t just develop your ideas; you’ll actually get to test them.

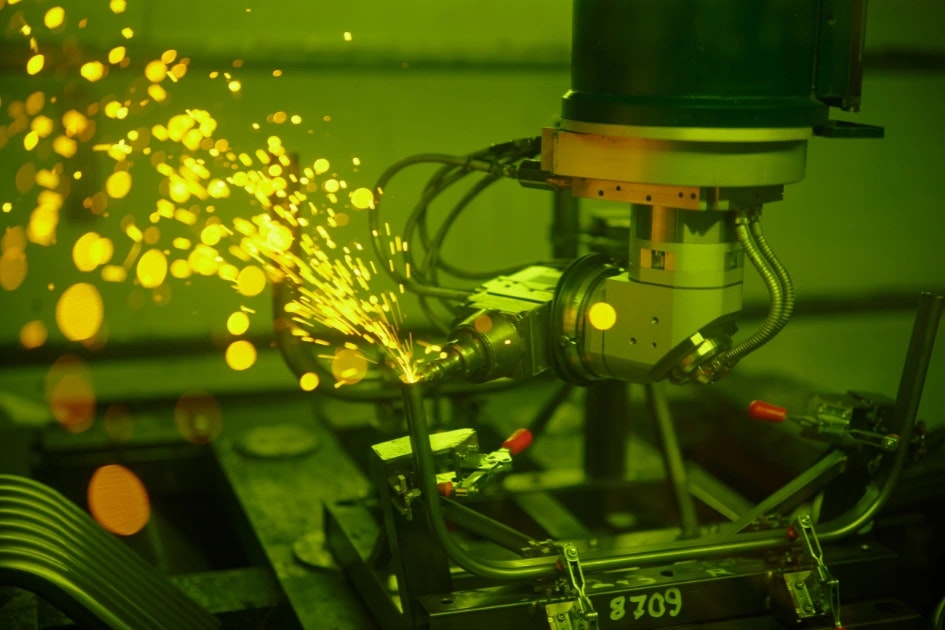

Laser cutting and welding robots: precision, flexibility, and automation in-house

Here, we combine advanced technology with craftsmanship. With our modern laser cutting machine, we quickly and accurately produce frames for our unique bicycles. This enables us to respond flexibly to customization and innovation without depending on external suppliers.

Our six advanced welding robots ensure fast, precise, and consistent connections, guaranteeing top quality at all times. For you as an employee, this means working in a modern production environment where automation and craftsmanship go hand in hand. You’ll have the opportunity to program, optimize, and continuously improve the welding robots together with colleagues, directly contributing to innovative and sustainable mobility.

3D Printing: innovation in every layer

3D printing is now indispensable in the innovation process at vanRaam. This technology allows us to rapidly develop prototypes, unique components, and smart tools. That means: less waiting, more testing, and faster improvements. You’ll work directly with the latest 3D printers and materials, bringing your ideas to life in no time.

Why is this so important? In the world of adapted bicycles, every millimeter counts. Thanks to 3D printing, we can provide tailor-made solutions for our users and quickly respond to real-world feedback. Together with colleagues from different disciplines, you’ll design solutions, print components, and test them directly on our bicycles. This way, you experience the power of innovation up close.

Scanbox at vanRaam: quality guaranteed down to the smallest detail

The scanbox is a crucial part of our quality process at vanRaam. With this advanced 3D measuring machine, we check every frame with millimeter precision. This ensures that every component meets our high standards and fits perfectly into the final product.

Innovation at vanRaam also means space for your personal growth. You’ll have the opportunity to learn, experiment, and develop yourself in an environment where innovation is the norm. Whether you have a technical background or a creative mindset, your contribution makes an impact.

The Idea Factory: where innovation becomes tangible

The vanRaam Idea Factory is where the real magic happens. This is not just an ordinary workshop, but a breeding ground where creativity and craftsmanship come together. Here, we design and build solutions that make our bicycles smarter, more practical, and more beautiful. Not just thinking, but especially doing, that’s our approach.

Jolien puts it perfectly: “The Idea Factory is our creative workshop where we try out new things that make our bicycles even better, more practical, and more beautiful. We also continue to further develop existing bicycle solutions. How do we do that? Our designers, craftsmen, interns, and graduates continuously strengthen each other and bring the best ideas to life together. Our dealers and the cyclists themselves also play a role in this. We don’t just think of ideas, as soon as possible, we test them in practice. Every solution we come up with has to work flawlessly in daily life. Off the paper, onto the wheels with the idea.”

In the Idea Factory, everything revolves around collaboration. Designers, craftsmen, interns, and graduates bring their knowledge together, refine each other’s plans, and make ideas tangible right away. We listen to dealers and cyclists, because they know better than anyone what really works. This way, we improve existing solutions and dare to experiment with entirely new ones.

Proof? Take the Thuja, our latest innovation. In the Idea Factory, we make the transition to a tricycle logical and accessible. A solution born directly from real-world practice and one that immediately proves its value there.

In the Idea Factory, no idea remains just on paper. Everything gets the chance to conquer the world on wheels.

Did you know?

Every year, we test dozens of new components.

Every frame is scanned with millimeter precision.

We collaborate with students on innovative projects and prototypes.

Careers at vanRaam

Do you want to make a difference at vanRaam? Take the leap today: discover everything about working at vanRaam or view our vacancies directly. Your story starts here.

Do you have any questions?

We're happy to help! Contact our recruiter Britt.